HOW DOES A MIG WELDER WORK?

Two byproducts of electricity are heat and light, MIG welding uses the heata of elecctricity to melt twopieces of metal together. Your welding machine uses a transformer to lower and raise the amperage of the electricity coming out of your household 110v outlet, changing the amperage changes the amount of heat. The tip of the welder (not the large shielding cup) is where the electricity comes out. The wire that you weld with is called an electrode. When you pull the trigger on the gun the electricity is waiting to go somewhere (kind of like your home outlets have electricity waiting to go into an appliance). When you touch the nozzle on the welder to the metal and pull the trigger electricity flows and arcs (sparks) from the wire sticking out of the gun tip to the metal, and continues thru the metal pieces you are welding to the ground clamp and back to the machine. When you hook on the ground clamp, a complete path is made for the electricity to travel through – you have made a circuit. Without a complete circuit electricity will not flow.

Without shielding gas welding is a messy process. A weld without shielding gas is porous, hot liquid steel reacts to the Nitrogen in the air all around us. that is 78% Nitrogen and 21% Oxygen. The remaining 1% is tiny amounts of other gases like argon, carbon dioxide and methane. Gas pockets of Nitrogen are bubbles trying to rise up in a really thick, hot liquid. You are in effect boiling the steel. Some bubbles rise up enough to burst and leave a crater on the surface. Some are still inside the steel as it cools and solidifies. We don’t want no swiss cheesy weld.

Working with Electricity: Could I get shocked?

No, you won’t, as long as you don’t put your hand between the nozzle and the metal – you won’t do that (it would be like taking out a pen and paper to write and putting your hand between the pen and the paper it doesn’t work that way… You may have heard that electricity follows the path of least resistance. Metal is highly conductive, the electricity has a much easier time flowing thru the metal than your hand. You can even rest your bare hand on bare metal without danger of shock, however be safe and wear gloves to protect yourself from the heat of welding mainly and provides electrical insulation.

Take the time to properly position your gun so that you can see the full stick out length of your welding electrode wire (from tip of gun to metal your are welding). If you do not have a clear view with your hood up, you certainly won’t see when your hood is down and its dark.

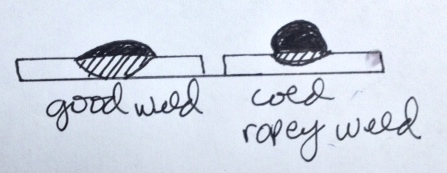

Pick up your steel and take a look at it on edge. A good weld bead lays fairly flat and fully penetrates the thickness of steel. Whereas a cold ropy weld looks like a piece of rope sitting on top and does not slump down on the edges but rather sits on top.

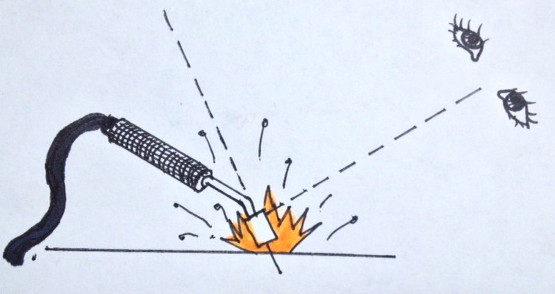

Remember: Hot metal burns, sharp metal cuts, bright light hurts eyes.

Welding hood: always have your hood on when watching welding

“Fire in the hole!” Give a shout to alert others around you, give them a moment to turn away

Use pliers to pick up metal after you weld on it – stays hot for a while

Wear safety glasses when filing or sawing

Wear leather gloves or pliers when handling the metal (until you are sure it is no longer hot)

Even hacksawing can heat up metal – be careful

Welding Tips

Look at the cheat sheet on the inside of your welder to get a general idea of the proper settings.

*Match the consumable copper screw on welding tip to wire size.

*Attach your ground clamp (to the work whenever possible.

*Land on the planet ! ! ! (Stabilize your body and hands).

*Keep two hands on your gun at all times ! ! !

*Stick out length is 1/4” to 3/8”. Touch the wire to your piece to start.

*Make a V so that you don’t block your own view.

*Weld slowly. Keep wire length short (most common problem areas). Students constantly say that the wire is coming out too fast and therefore is too long, if it is too long you need to move the tip of the gun closer to the work, this will shorten the wire length.

*Weave back and forth to increase your chances of welding both pieces of metal.

*Stay in the puddle, a popping sound means you are too far away or too fast

*Good wire speed and amperage will produce a fairly low profile weld with a “scar” on the backside. You want to hear a sound like bacon frying.

*A tight fit between pieces is preferable, 1/16th of an inch or so. But you can certainly fill a gap.

Troubleshooting

If your weld has rolled over edges or does not hold: turn up the heat / or decrease the wire speed. The stick out length may be too long.

If you feel the wire pushing back at you: turn down the wire speed, the wire should melt instantly.

If you keep missing the weld joint: increase the width of your weave

If the wire feeds erratically: straighten out your wire hose

If the machine makes a strange humming noise and stops welding: clean out the tip and cup of the gun, the welder has ground itself out.

If you are burning holes through the work piece: turn down your heat (voltage)

If the wire is melted to the gun tip your stickout length was too short: Try shaking the wire feed hose, grabbing the melted ball of wire electrode with pliers, or as a last resort filing off the melted end of wire. If you cannot free the wire you must cut the wire off (do not let spool unravel) and unscrew the ruined tip and replace with a new one.

Where to Buy Steel

Everett Steel: 3434 16th Ave. W. (in Ballard) 206-282-8694 has round tubing

Metal Supermarkets: 22029 70th Ave. S. Kent 253-395-1835 will precision cut sheet for you

Metal Shorts: 4101 W. Marginal Way S.W. 206-382-0305 has stainless steel

Pacific Industrial Supply: 1231 S. Director St. 206-682-2100 has a “junk” yard attached with all kinds of strange and beautiful stuff to make metal art with. Bring your magnet to make sure it’s mild steel. Stay away from galvanized metal, the fumes could make you sick. You can weld painted metal, but you would want to scrape away the paint from the weld area, and you want a well ventilated area – you don’t want to breathe the stuff.

Pacific Iron & Metal: 2230 4th Ave. S. 206-628-6237 has new and “used” steel, lots of fun to browse. Sheet metal is cut with a torch (ragged edge)

Where To Purchase Ornamental Steel by online

Architectural Iron Designs, Inc. has a full catalog is on the web at www. archirondesign.com most items do not have a minimum order requirement. Their phone # is 1-800-542-2379

King Architectural Metals at Kingmetals.com is also a great source for ornamental steel and is generally less expensive.

Where to Rent Equipment

Central Welding: 5401 4th Ave. S. (206)-766-9353 and 841 N.W. 49th (206)-783-2283 These guys are the best! I have gotten much good advice from them. They have several locations. This is a good place to buy helmets, gloves and welders etc. Ask for your 15% student discount.

Airgas: 4401 Airport Way S. 206-682-2880 This place just rents welders and plasma cutters

You want to rent a 110 volt MIG welder and buy self-shielding wire to start. If you weld a lot you will probably want to buy a gas tank – over the long haul this is cheaper, a small tank will cost you about $120. You can also rent plasma cutters from these shops. Ask the rental shop to set up the MIG welder with the correct polarity for you to weld with self shielded wire, you want DCEN (electrode negative) for self shielded wire.